In every production and farming activity, Vinamilk is committed to using water in the right place, at the right time, for the right purpose, and in the right amount.

Loving the Earth

For Vinamilk, the Earth is more than a source—it’s our partner

We see the Earth as the foundation of all resources and a true companion on our journey toward sustainability.

Loving the Earth means acting with intention: reducing our carbon footprint, leading the way in green energy and technology, managing natural resources responsibly, minimizing waste, and planting trees to restore green spaces across Vietnam.

A Sustainable Journey Needs Collective Effort

Not a Luxury Game

“Everyone is being affected—negatively. Even our daily meals are starting to bear the weight of this reality. I believe Net Zero is not a luxury reserved for the wealthy. It is a duty, a responsibility, and above all, a right—to a better, safer life for all.”

Part of a Shared Value Chain

"Reducing emissions isn’t the responsibility of a single company—we’re all part of a shared value chain. Vinamilk works with suppliers and serves consumers, and their activities also generate emissions. That’s why this challenge can’t be solved alone. It requires collective action from businesses and the broader community."

An Opportunity for Every Business

"From very early on, Vinamilk recognized that sustainable development is not just an option—it’s the only way forward. When viewed through that lens, any business—regardless of size or resources—can build its own sustainability strategy."

Driven by Responsibility

“The motivation to act must come from a deep sense of responsibility toward the environment and the community. Vinamilk began by complying with environmental laws and regulations. From there, we’ve grown into proactively and voluntarily adopting sustainable practices—publishing sustainability reports, and investing in green technologies and solutions.”

Pathways to Net Zero 2050

Vinamilk is proud to be the first dairy company in Vietnam to join the Global Dairy Net Zero Initiative, leading the way with its ambitious “Vinamilk Pathways to Dairy Net Zero 2050” program. As of 2025, three of Vinamilk’s facilities have achieved international Carbon Neutrality Certification.

Reduce 15%

of emission

Reduce 55%

of emission

Achieve Net Zero

Complete roadmap

Efforts to Reduce Our Carbon Footprint

Over 1.1 million trees

across Vietnam (2012–2025)

Over 3% CO₂e

per ton of product

86,2% of fossil energy

with renewable energy in production

Protecting water resources

4,99%

of water used in production is recycled and reused

85%

of treated livestock wastewater is reused for crop irrigation

100%

of wastewater from factories and farms is treated to meet environmental standards before discharge

*In 2022, groundwater usage decreased by 5% compared to 2021

48.180 m³

recovered and reused through the reverse rinsing water recovery system

22.464 m³

saved by optimizing cooling water use in homogenizers

9.945 m³

recovered and reused from the cooling water recirculation system on carton filling machines

750 m³

recovered and reused by using rainwater to clean milk tank trucks

“Protecting and Using Water Efficiently Is Paramount”

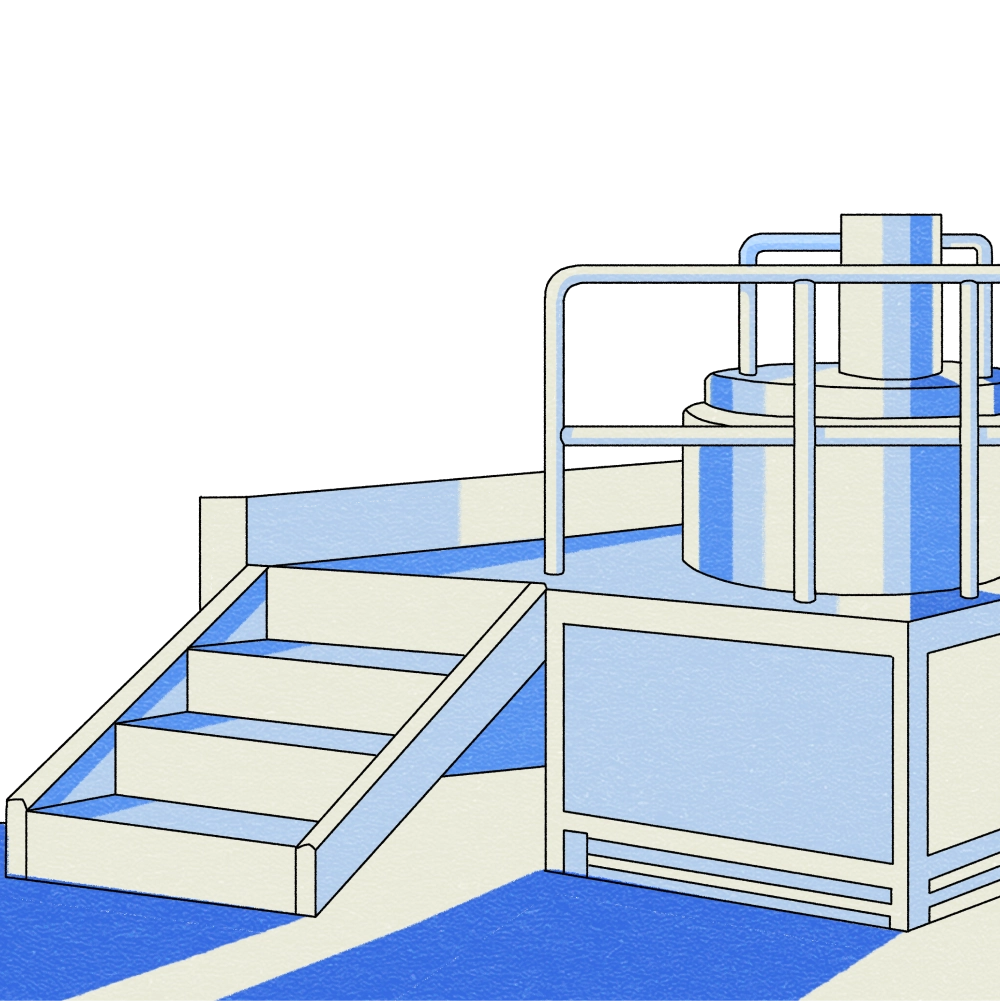

Reverse rinsing water recovery system

In 2023, Vinamilk installed a reverse rinsing water recovery system at Tien Son Dairy Factory. Previously, all reverse rinsing water from filter cleaning was discharged directly into the wastewater treatment system—wasting valuable water and increasing treatment loads. With the new system: rinsing water is collected into a storage tank, then treated to meet clarity standards and reused in production, saving up to 48,180 m³ of water annually, which help reduce electricity consumption and cut CO₂ emissions.

Cooling water optimization for homogenizers

In dairy processing, homogenizers operate under high pressure, requiring significant amounts of cooling water to maintain stable performance. Through in-depth research and system analysis, Vinamilk identified the optimal cooling water volume needed—ensuring both equipment stability and water efficiency.

As a result, the factory successfully reduced cooling water usage by 66% and saved approximately 22,464 m³ of water annually.

Cooling water reuse system for carton filling machines

Previously, cooling water from the heat exchangers on carton filling machines was discharged after use—leading to unnecessary waste. In 2023, Vinamilk engineers repurposed existing equipment such as storage tanks and heat exchangers, designed and installed a custom water recovery system, and cooled and recirculated the recovered water back into the production process. As a result, our factory now saves up to 9,945 m³ of water annually, contributing to both environmental conservation and operational efficiency.

Rainwater harvesting for milk tanker cleaning

At the fresh milk receiving area, Vinamilk previously relied on municipal water to clean the exterior of raw milk tankers. In a smart sustainability upgrade, our factories repurposed existing storage tanks, installed a rainwater collection system with new piping, and now use harvested rainwater to clean the tankers during the rainy season. As a result, our factories no longer use municipal water for this purpose during rainy months—saving up to 750 m³ of water annually.

Soil nurturing

Waste reduction: turning waste into resources

Target: 100%

Our commitment: the 3 NOs

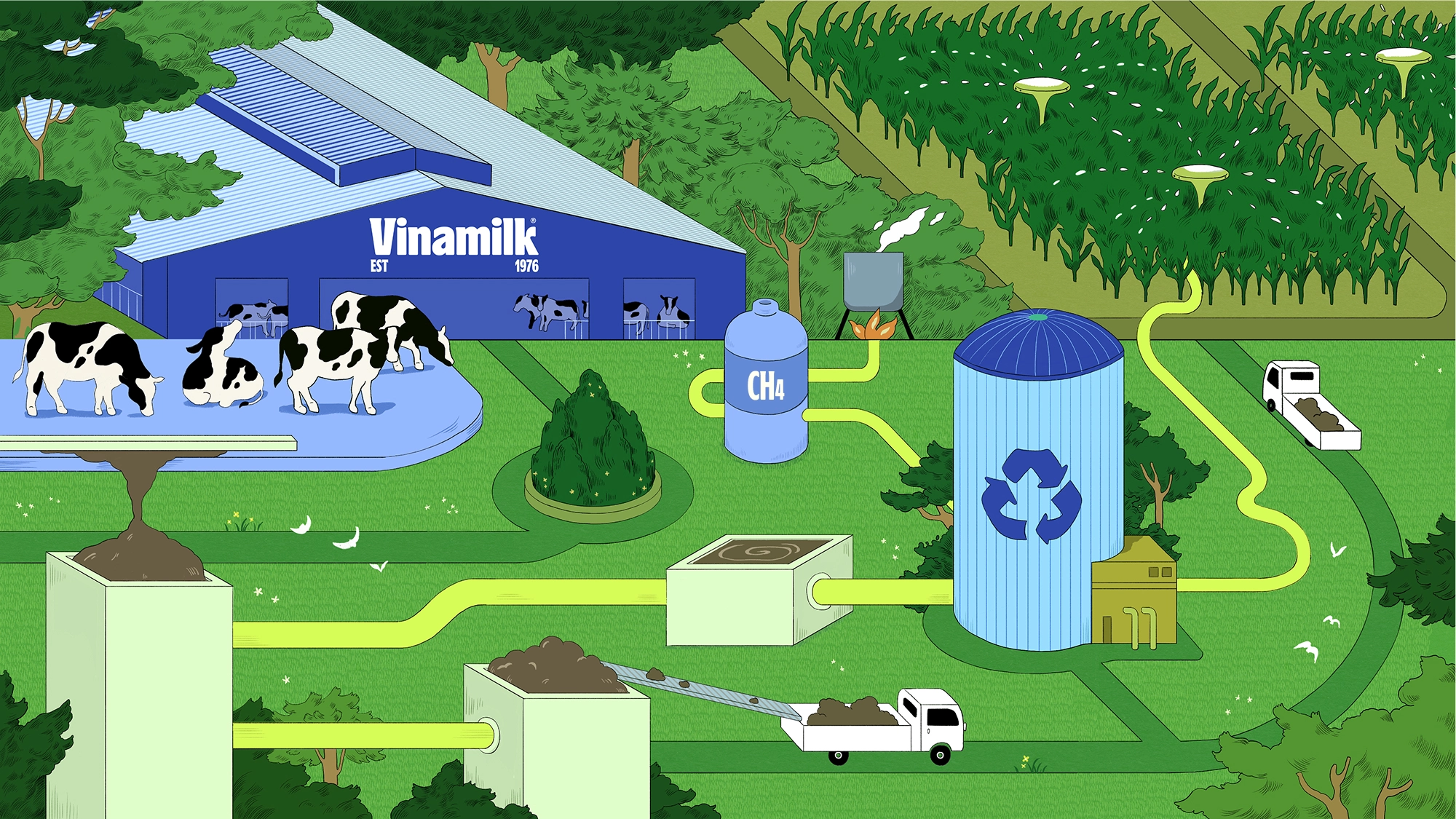

100% of our farms utilize biogas systems to transform cow waste into valuable resources.

Towel and workwear dryers powered by biogas energy

Grass dryers powered by biogas energy

Biodiversity conservation

Maintaining vegetative cover

Investing in sustainable agriculture

Regenerative agriculture is the inevitable path to a sustainable future.

Leading the way in regenerative agriculture investment

In 2025, Vinamilk aims to implement soil health assessments across all of our farms—starting with Green Farm Tay Ninh—to pave the way for personalized soil nutrition, optimized fertilizer use, and enhanced natural organic content.

Crop rotation and no straw burning

Implemented at our organic farms and gradually extended to traditional farms, this practice helps maintain soil fertility and promote biodiversity.

Utilizing organic fertilizer

All of our farms make full use of compost and liquid fertilizer generated from the biogas system—providing natural nutrients to the soil while reducing reliance on chemical fertilizers.

On-site biodiversity conservation

715 hectares of natural grassland—accounting for 30% of our agricultural land—serve as vital habitats for beneficial predatory species

Continue reading

Caring for Communities